What is the cost of manufacturing development services at Limeup?

The cost of manufacturing development services at Limeup varies based on several factors, including the complexity of the project, the scope of services required, and the timeline. Limeup understands that every manufacturing business has unique needs, which is why we provide tailored pricing to ensure clients receive the most value for their investment.

Limeup uses a transparent pricing strategy with no hidden fees. Our organization normally gives a full breakdown of prices from the start, allowing businesses to make informed judgments. It promotes clarity throughout the development process, providing our clients with confidence that there will be no unexpected charges.

Furthermore, Limeup’s low pricing does not compromise quality. We supply solutions created with the latest technologies and a heavy emphasis on long-term sustainability, resulting in a high return on investment.

Limeup’s highly skilled engineers work hard to fulfill your specific business demands while always prioritizing quality and efficiency. Businesses that partner with us receive access to modern software solutions that accelerate operations, increase efficiency, and drive growth — all at a reasonable cost.

What are the primary types of software used in manufacturing?

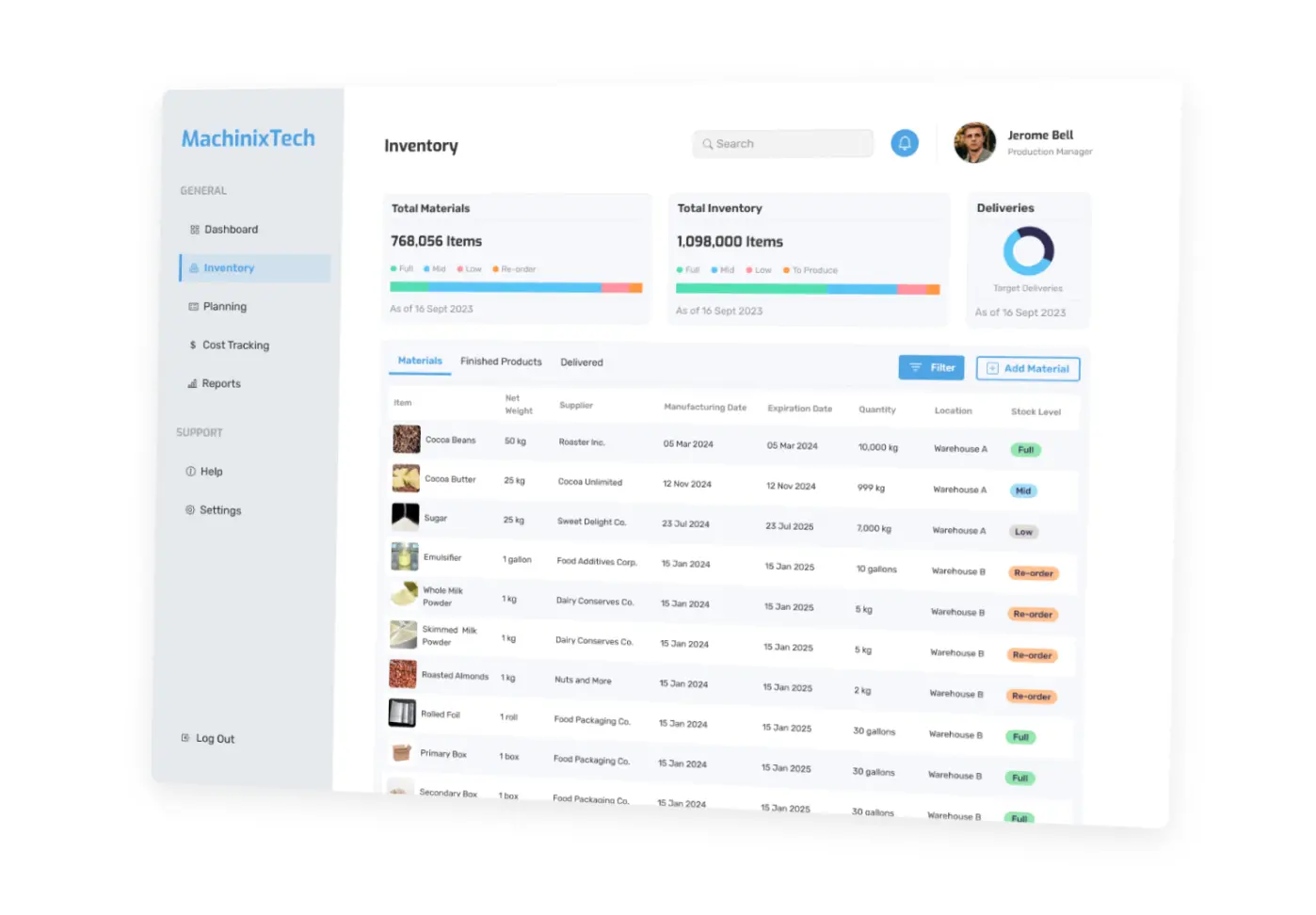

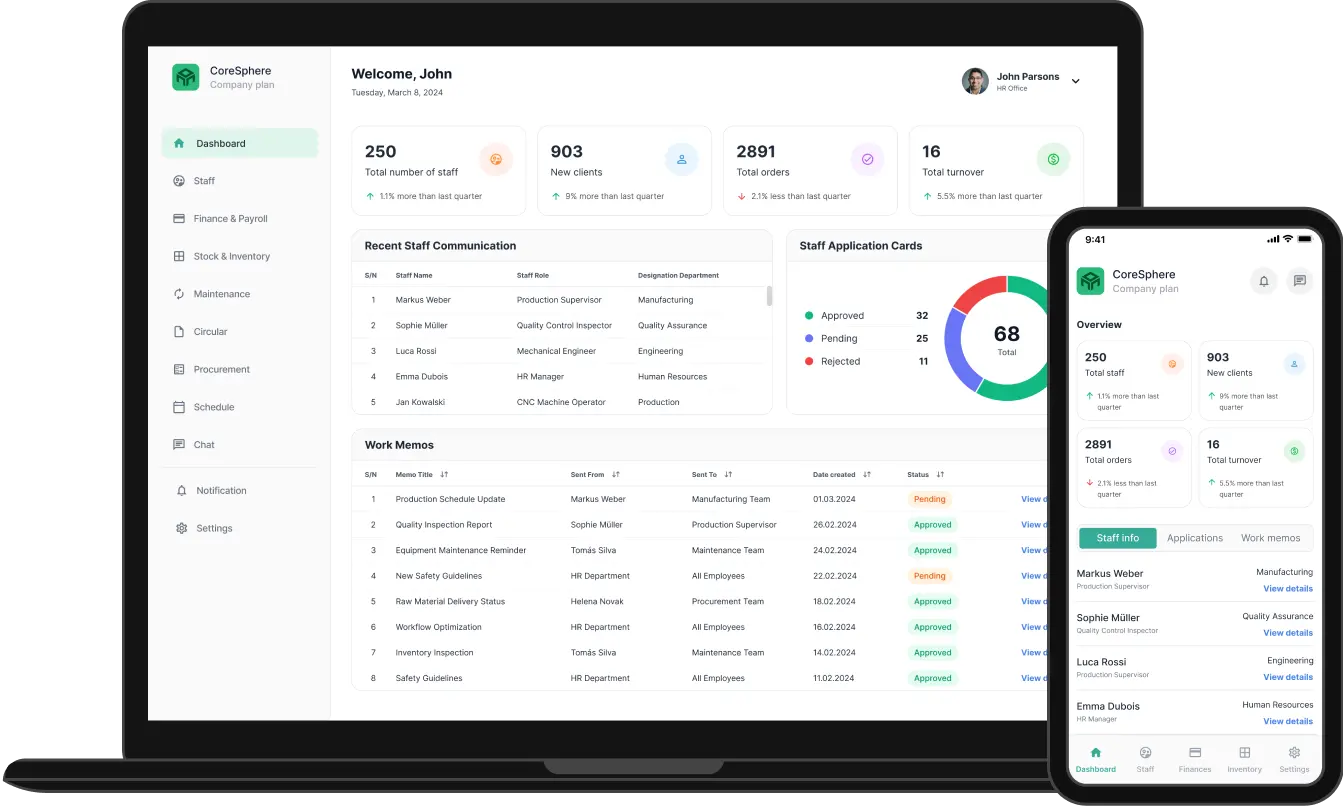

In the manufacturing industry, several software types are essential for optimizing operations. Enterprise Resource Planning (ERP) systems integrate business processes across departments, from inventory management to finance, providing a unified platform for real-time insights. Limeup excels in developing customized ERP solutions that enhance operational efficiency and offer comprehensive visibility into manufacturing workflows.

Manufacturing Execution Systems (MES) bridge the gap between production and management, tracking real-time data from the shop floor to improve efficiency and quality. Limeup has significant experience in creating MES solutions that seamlessly integrate with existing systems, providing manufacturers with the tools they need to minimize downtime and improve decision-making.

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are crucial for product design and machine operation. CAD software helps create precise product designs, while CAM translates those designs into machine instructions. Limeup works with clients to develop tailored CAD and CAM solutions, ensuring they are optimized for specific production needs.

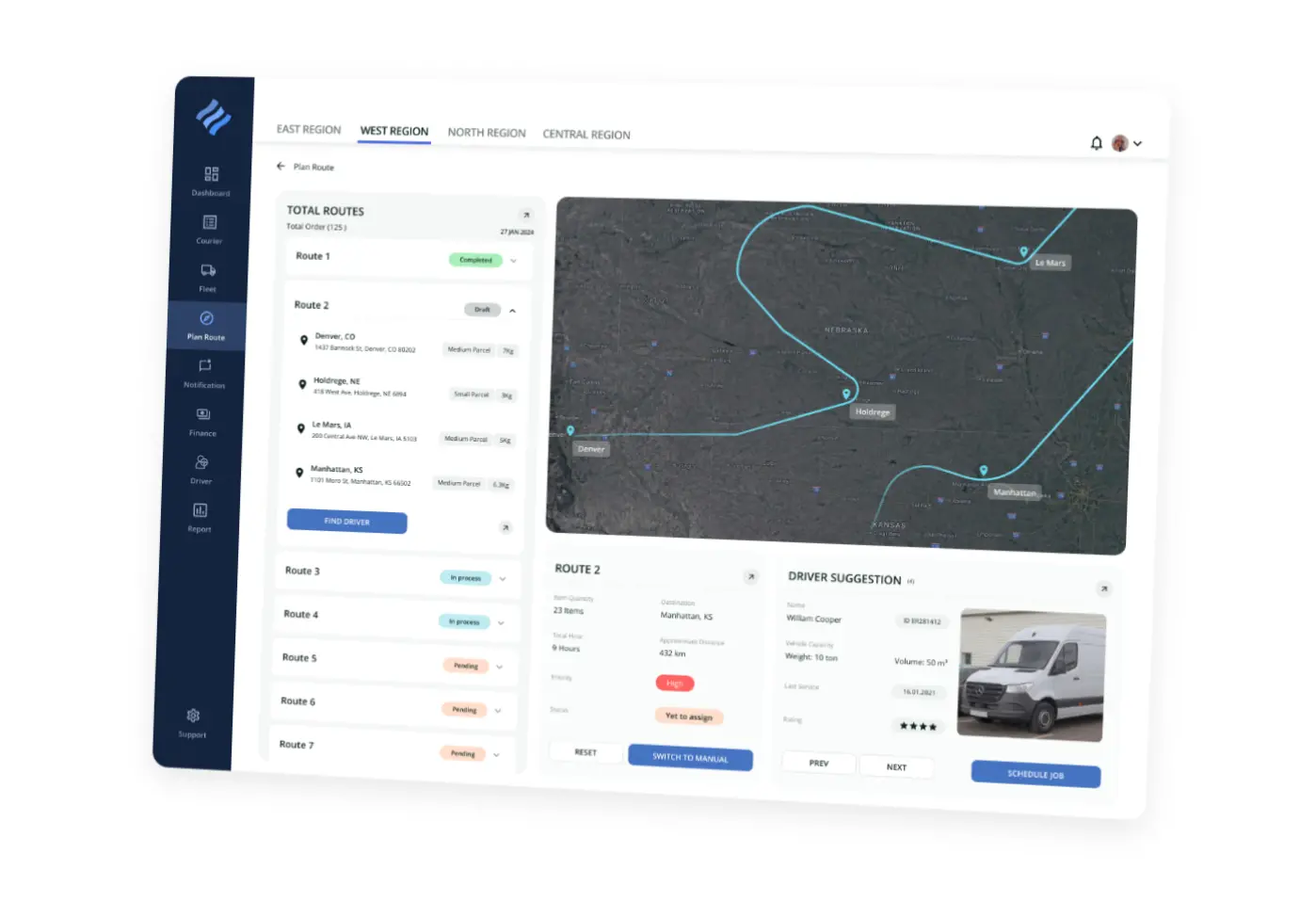

Finally, Supply Chain Management (SCM) software optimizes the movement of materials and products across the supply chain. Limeup’s deep knowledge of SCM solutions helps manufacturers improve procurement, logistics and inventory management, ensuring products are delivered on time and cost-efficiently. Through tailored software, Limeup enables manufacturers to streamline operations and stay competitive in a rapidly evolving market.

How does using IoT and AI technology in manufacturing software help with quality control and product innovation?

The synergy of IoT (Internet of Things) and AI (Artificial Intelligence) within manufacturing software is a game changer for enhancing quality control and fueling product innovation. Here’s a closer look:

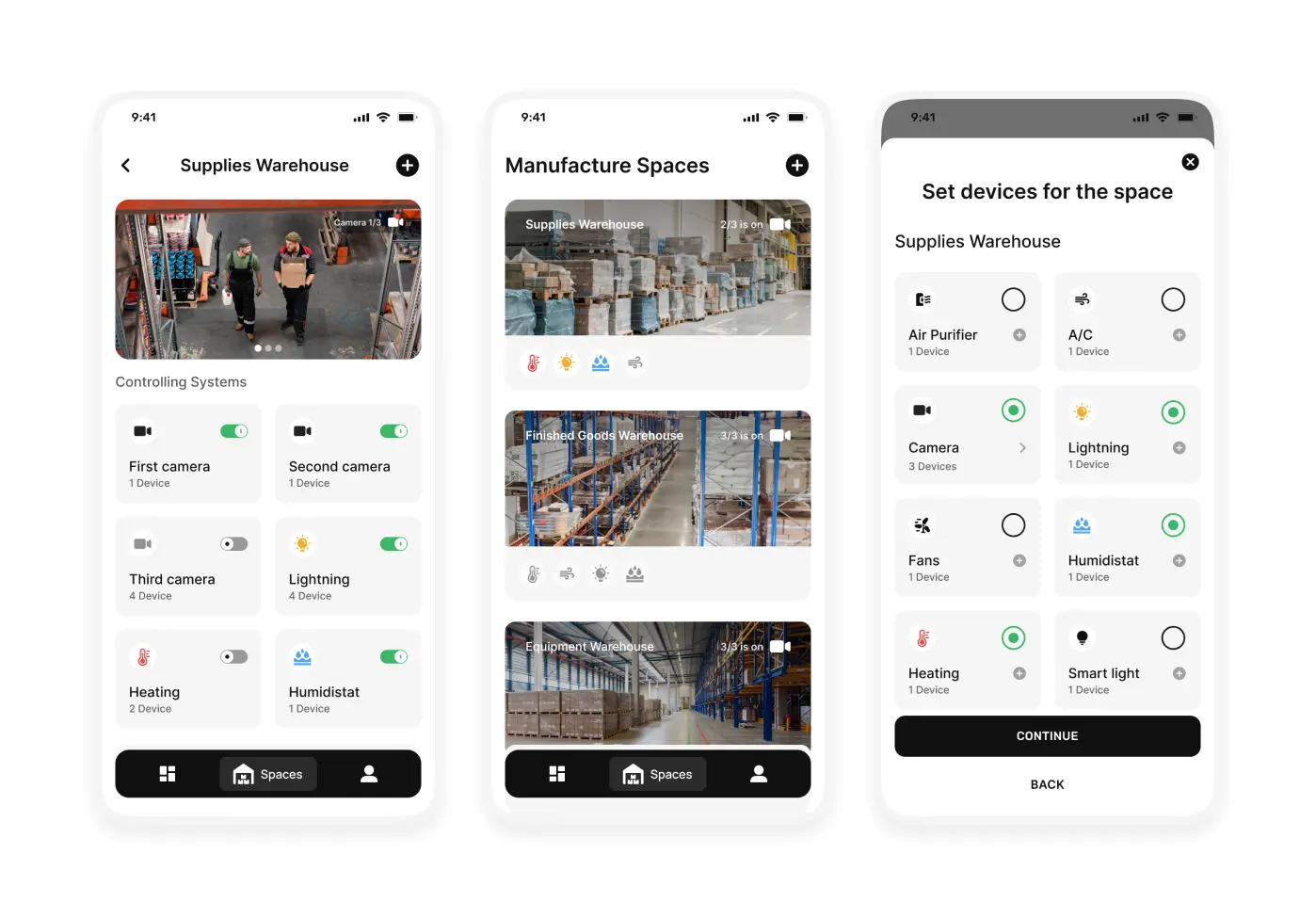

- Enhanced quality control with IoT. IoT devices, such as sensors and connected machines, collect real-time data from the production line, offering manufacturers deeper visibility into equipment performance and product quality. By tracking factors like temperature, pressure and machine health, IoT systems can flag irregularities before they impact the final product, enabling proactive maintenance and ensuring consistent quality.

- AI-powered data analysis. AI technologies take the data gathered by IoT devices to the next level by analyzing it for patterns, trends and anomalies. AI algorithms help optimize production processes, automate quality control checks and make informed decisions. Also, AI can power visual inspection systems, automatically detecting defects in products, reducing the need for manual inspections and minimizing human error.

- Driving innovation. Together, IoT and AI enable manufacturers to innovate continuously by improving product design and process efficiency. By leveraging these technologies, businesses can develop smarter, more sustainable products that meet evolving market demands while reducing waste and downtime.

At Limeup, we guide manufacturers through the process of embedding IoT and AI into their software, optimizing quality assurance and sparking innovation, so you can maintain a competitive edge.